Beyond the Blueprint: Unconventional Thinking in Free Boat Building

How to Make Your Own Free Boat with Easy-to-Follow Plans promises a dream â€" a free boat built by your own hands. But what if we looked beyond the literal “free†and explored the truly unconventional aspects of this endeavor? This review delves into those often-overlooked perspectives, addressing the less-discussed challenges and opportunities inherent in crafting your own vessel.

The "Free" Factor: Beyond the Material Cost

The title’s allure hinges on the promise of free materials. While scavenging for reclaimed wood can drastically reduce costs, it introduces significant complexities. How often do we truly consider the hidden costs?

Q: What’s the real cost of "free" boatbuilding beyond materials?

A: The time investment is substantial. Research suggests that even simple boat projects can consume hundreds of hours. Factor in the cost of your time, including lost income opportunities. Then there's the potential for mistakes â€" requiring extra material, tools, or even professional help, effectively negating the initial cost savings. Plus, consider the environmental impact of sourcing and disposing of materials.

Q: How can we re-evaluate the "free" aspect sustainably?

A: Focus on minimizing environmental footprint. Collaborate with local recycling centers or demolition companies for reclaimed wood, reducing transportation costs and carbon emissions. Document the entire process meticulously, creating a valuable resource for others interested in sustainable boat building. This documentation could become a unique selling point, offsetting some costs.

Beyond the Plans: Innovation and Customization

While "easy-to-follow plans" are attractive, they can stifle creativity. Let's explore the potential for personalized boat design.

Q: Can we enhance existing plans with modern design principles?

A: Absolutely! Incorporating elements of hydrodynamic design, even on a small scale, can drastically improve performance. Utilizing readily available online resources on topics such as hull design, stability calculations, and even 3D modeling software can add a significant level of sophistication. This transforms the project from simple construction to a sophisticated engineering endeavor.

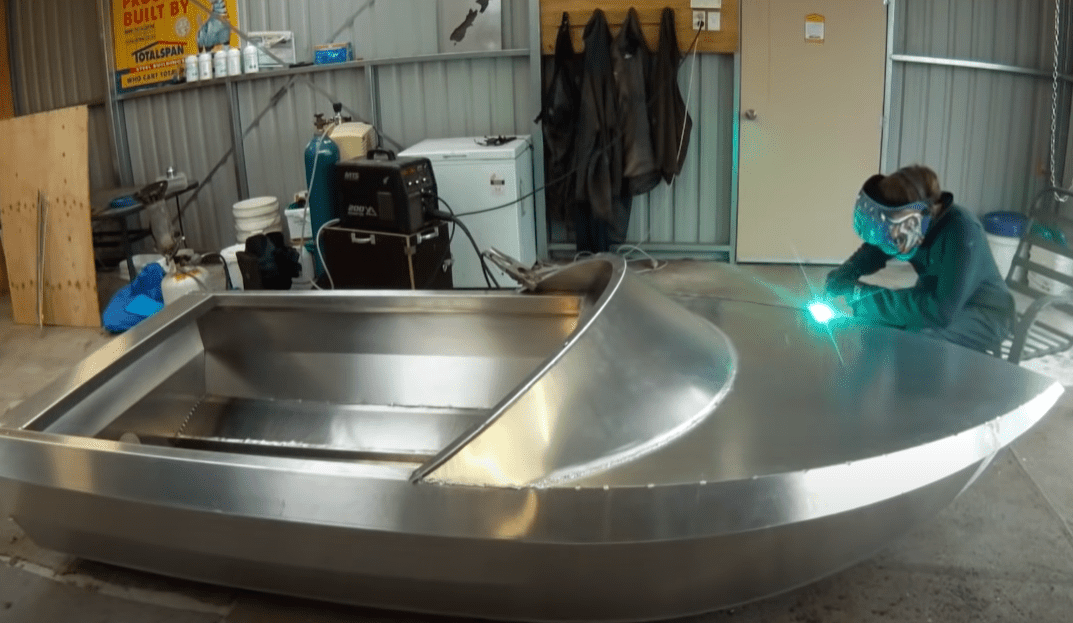

Q: How can we leverage digital fabrication techniques?

A: Explore the use of CAD software and CNC routers for precision cutting, especially for complex curves. Although requiring an initial investment, this approach can significantly reduce labor, minimize waste, and increase accuracy â€" leading to a more robust and efficient build. This also opens up opportunities for exploring more advanced designs beyond the constraints of traditional plans.

Real-World Lessons: Learning from Experience

Let's learn from those who’ve undertaken similar projects.

Story 1: A woodworking enthusiast, inspired by the book, built a small sailboat. Initially elated by the "free" aspect, he later realized the hidden costs of time and unforeseen challenges. However, the experience fueled his passion for boatbuilding, leading him to pursue further training and eventually design his own unique vessel.

Story 2: A group of students, as part of a community project, used the book as a starting point but incorporated recycled plastic bottles into their design, demonstrating ingenuity and environmentally conscious boat building.

Conclusion: Redefining "Free" Boatbuilding

How to Make Your Own Free Boat with Easy-to-Follow Plans offers a valuable starting point. However, its true value lies in inspiring unconventional thinking. By embracing creativity, sustainability, and modern fabrication techniques, we can redefine "free" boatbuilding as a journey of innovation, learning, and personal fulfillment â€" far beyond the simple avoidance of material costs.

For hobbyists, this means pushing creative boundaries. For educators, it presents opportunities for integrating design thinking and sustainable practices into curricula. For craftsmen, it highlights the potential for combining traditional skills with modern technology. The book provides a foundation; it's up to us to build upon it.