Beyond the Blueprint: Unlocking Your Dream Boat's Potential

Building a boat from scratch is a monumental task, a testament to human ingenuity and craftsmanship. While countless resources detail the process, How to Customize Boat Building Blueprints for Your Ideal Boat (let's call it "the book") provides a solid foundation. However, true mastery comes from venturing beyond the surface, asking the hard questions, and thinking outside the traditional blueprint. This review doesn't just summarize the book; it explores the unspoken challenges and unique solutions rarely discussed in typical boat-building literature.

The Unspoken Challenges: Beyond the Lines on the Paper

The book effectively covers standard blueprint customization, but what about the nuances? The intangible aspects that significantly impact the final product?

Q: How do you factor in your *personal* building limitations?

A: The book rightly emphasizes adapting dimensions, but it overlooks the crucial element of *builder skill*. A seasoned craftsman can tackle complex curves; a beginner might need to simplify the design. Consider this: a novice builder might choose to substitute a complex, curved transom for a simpler, more easily constructed one, even if it slightly compromises aesthetics. This isn't a failure; it’s smart adaptation. Documenting these choices alongside the blueprint modifications is vital for future projects and troubleshooting.

Q: What about material availability and cost fluctuations?

A: Blueprints often specify particular wood types. But what if your chosen lumberyard doesn't stock mahogany, or the price is prohibitive? The book touches on material substitution, but doesn't fully explore the logistical and cost-implications. This requires research â€" comparing properties of alternatives (strength, rot resistance, cost) and factoring in transportation costs. A spreadsheet comparing various options could be a surprisingly powerful tool, transforming a seemingly insurmountable challenge into a carefully calculated decision.

Creative Solutions: Thinking Outside the (Hull) Box

Let's move beyond the reactive adaptation of existing blueprints and explore proactive customization. How can we truly make the blueprint *ours*?

Integrating Modern Technologies:

The book focuses on traditional techniques. However, integrating modern technologies can revolutionize the building process. Consider:

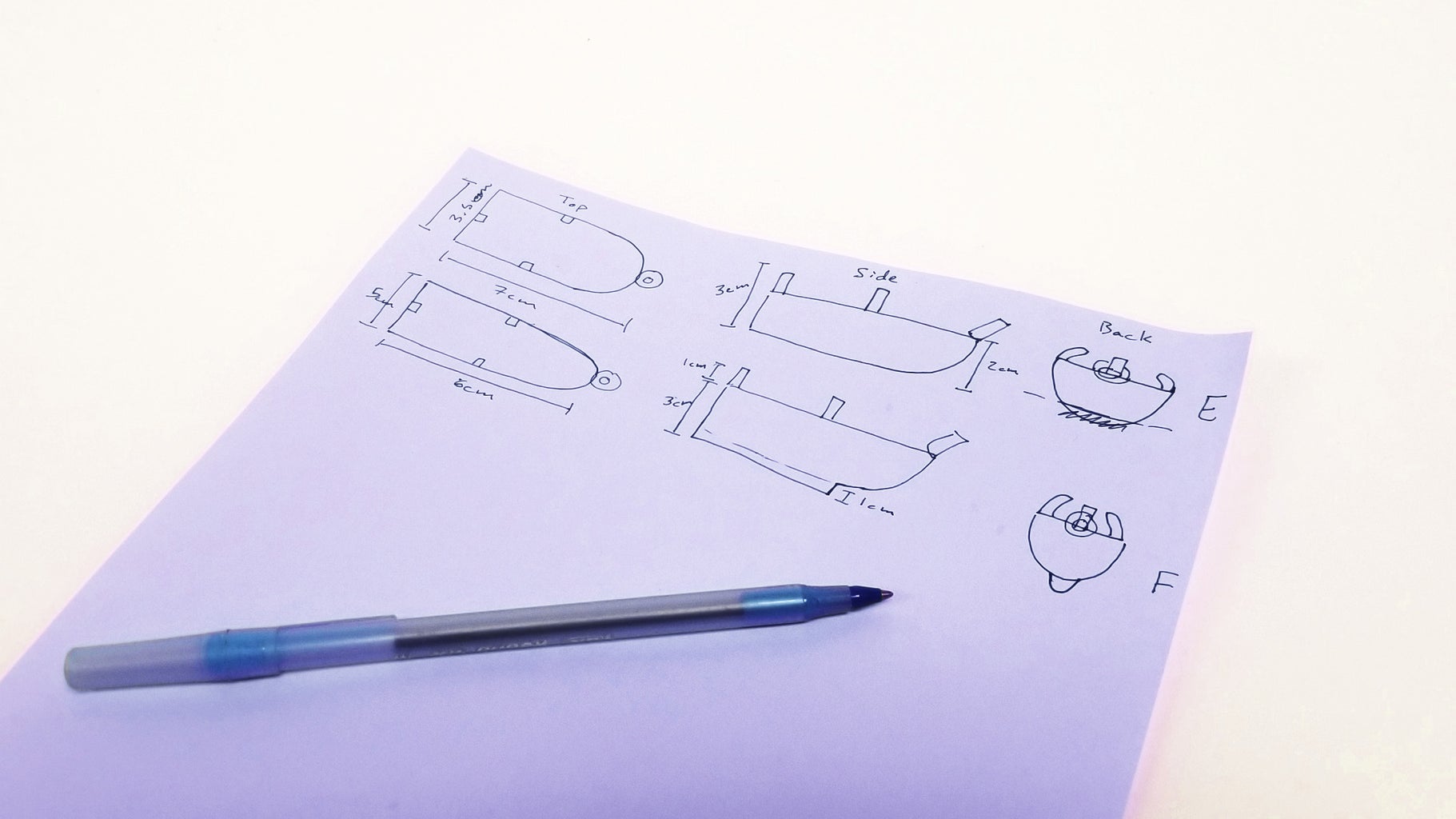

- 3D modeling software: Instead of relying solely on 2D blueprints, using software like Fusion 360 or Blender allows for a 3D visualization, enabling easier identification of potential problems and smoother modifications.

- CNC routing: While expensive, this can dramatically increase precision and efficiency, particularly for complex curves or intricate details. The initial investment can be justified if you plan to build multiple boats or specialize in a particular design.

- Laser scanning existing boats: For those aiming to replicate or improve upon an existing design, laser scanning can create a highly accurate 3D model as a basis for modification and customization.

The "Reverse Engineering" Approach:

Instead of starting with a blueprint and modifying it, consider starting with the *desired outcome*. What kind of boat do you *really* want? What are its essential features (speed, stability, storage)? Then, research existing designs with similar characteristics, studying their strengths and weaknesses. This reverse-engineering approach might lead you to a more suitable base blueprint than simply picking one at random.

A Real-World Example: The "Unexpected" Dory

A friend of mine, a seasoned woodworker, used the book as inspiration for building a dory. He initially followed the blueprint closely, but encountered difficulties sourcing the specified wood. Instead of abandoning the project, he creatively substituted readily available cedar, meticulously adjusting the design to compensate for the cedar's different properties. He documented everything, ultimately producing a beautiful and surprisingly robust dory that showcased his problem-solving skills and adaptability. His journey underscores the importance of flexible thinking and proactive documentation â€" qualities that the book subtly encourages, but doesn't fully emphasize.

In conclusion, How to Customize Boat Building Blueprints for Your Ideal Boat serves as a valuable guide. But its true potential unfolds when coupled with critical thinking, resourcefulness, and a willingness to experiment. It's not just about adapting blueprints; it's about creating a unique vessel that reflects your skills, resources, and vision.